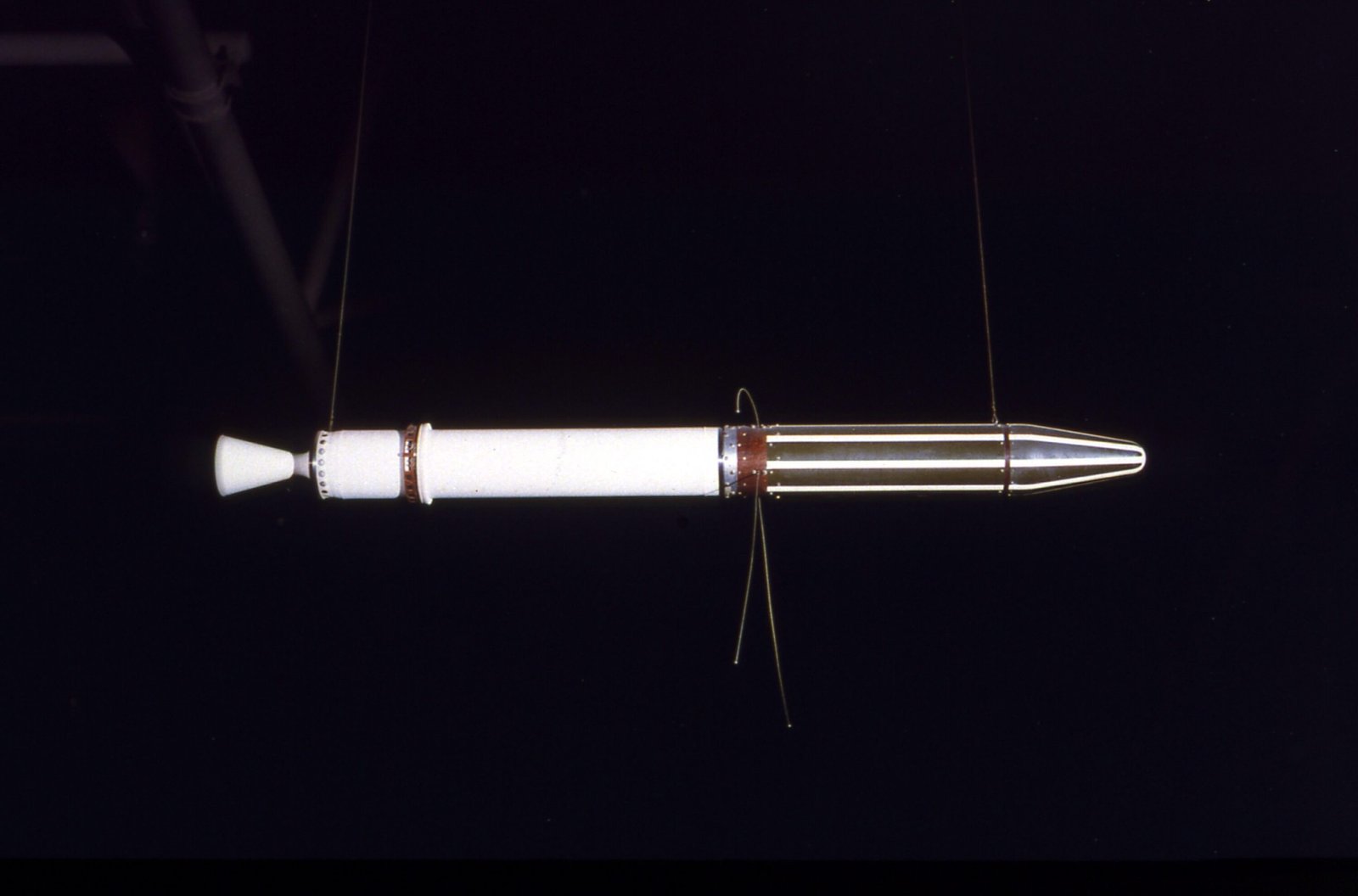

The Dragon was designed by SpaceX. The first of two practice flights were launched on December 8, 2010, and the second test flight, which conveyed cargo to the International Space Station (ISS), was propelled on May 22, 2012. The first maintained flight propelled on May 30, 2020, and conveyed astronauts Doug Hurley and Robert Behnken to the ISS.

Important features

- Built by SpaceX from the ground up.

In just 4 years, SpaceX prepared the DragonX from a blank sheet to its mission.

- First privately developed spacecraft to attach to the International Space Station (ISS)

In May 2012, Dragon became the first commercial spacecraft to deliver cargo to the ISS and return safely to Earth, a feat previously achieved only by governments. In October 2012, Dragon completed its second mission to the ISS, its first of 12 official cargo resupply missions for NASA.

- Payload capability

Dragon transfers payload in a pressurized case and an unpressurized trunk. It can transfer 6,000 kilograms (13,228 pounds), split between pressurized freight inside the container and unpressurized freight in the storage compartment, which likewise houses Dragon’s sun powered boards.

- Dimensions

DragonX is 4.4 meters (14.4 feet) tall and 3.66 meters (12 feet) in width. The storage compartment is 2.8 meters (9.2 feet) tall and 3.66 meters (12 feet) wide. With sun based boards completely expanded, the vehicle measures 16.5 meters (54 feet) wide.

- Advanced heat shield

DragonX has the best heat shield in the world. Designed by NASA and created by SpaceX, it is made of PICA-X, a superior variation on NASA’s unique phenolic impregnated carbon ablator (PICA). PICA-X is intended to bear heat rates from a lunar return crucial, far surpass the prerequisites for a low-Earth circle strategy.

- Smooth, controlled reentry

Dragon’s inactively steady shape produces lift as it reenters the Earth’s air. Its 18 Draco engines give move control during entrance to keep it decisively on course toward the arrival site before its parachutes convey.

- Designed for astronauts

Although this resupply mission carries only cargo, Dragon was planned from the start to convey the team. Under a $2.6 billion agreement with NASA, SpaceX is creating new designs for the moving team, including seating for up to seven space travelers, the most progressive dispatch get away from setup ever created, a propulsive landing framework, natural controls, and life-emotionally supportive networks.

Working Mechanism

- Draco Thrusters

Dragon’s 18 Draco engines allow orbital moving and powerful control. It is fueled by nitrogen tetroxide/monomethylhydrazine (NTO/MMH) storable forces; 400 N push is used to control the approach to the ISS, power takeoff from the ISS, and control Dragon’s disposition upon reemergence.

- Power

More than 5-kilowatt power is produced by the two solar array wings on the trunk. Dragon’s batteries are recharged by the surplus power for the time period when it is in darkness. Surplus power id always kept in the DragonX to counter the unfavorable conditions. In the low-Earth circle, Dragon is in obscurity about 40% of the time.

- Avionics

Dual issue tolerant processing gives consistent reinforcements to all basic flying parts, giving one of the most dependable structures to fly. This design setup supports the full body of the DragonX system to withstand with the air pressure. The RIOs (remote information/yield modules) give a typical figuring stage with configurable info and yield control cards.

- Communications

Communications between Dragon and the International Space Stations (ISS) are provided by the COTS UHF communications unit (CUCU). CUCU was delivered to the space station on STS-129. ISS crew commands Dragon using the crew command panel (CCP). Dragon can also communicate on S-band via either tracking or data relay system (TDRSS) or ground stations.

- Environmental Control System

Dragon’s cabin has air circulation, lighting, fire detection and suppression, air temperature control, pressure and humidity monitoring.

- Thermal Protection System

Primary heat shield: Tiled phenolic impregnated carbon ablator (PICA-X), fabricated in-house. Backshell: SpaceX Proprietary Ablative Material (SPAM).

- Transporting Crew

For moving cargos, Dragon was structured from the earliest starting point to ship team and is at present experiencing alterations to make this suitable. Group setup will incorporate life support systems, a team escape framework, and locally available controls that permit the team to take control from the flight PC when required. This emphasis on shared trait among payload and team setups limits the plan exertion and rearranges the human-rating process, allowing systems to Dragon crew security and ISS wellbeing to be completely tried on unmanned flights.